These days, when professionals from the Horeca sector embark on the design of an industrial kitchen, they should ask the following question: how can the possibilities of the space be optimised to make it as efficient as possible? On this basis, and in order to obtain maximum profitability from an industrial kitchen, there are certain aspects that should be considered. Today, Fagor Professional reveals the key to getting the best out of an industrial kitchen and increasing its profitability.

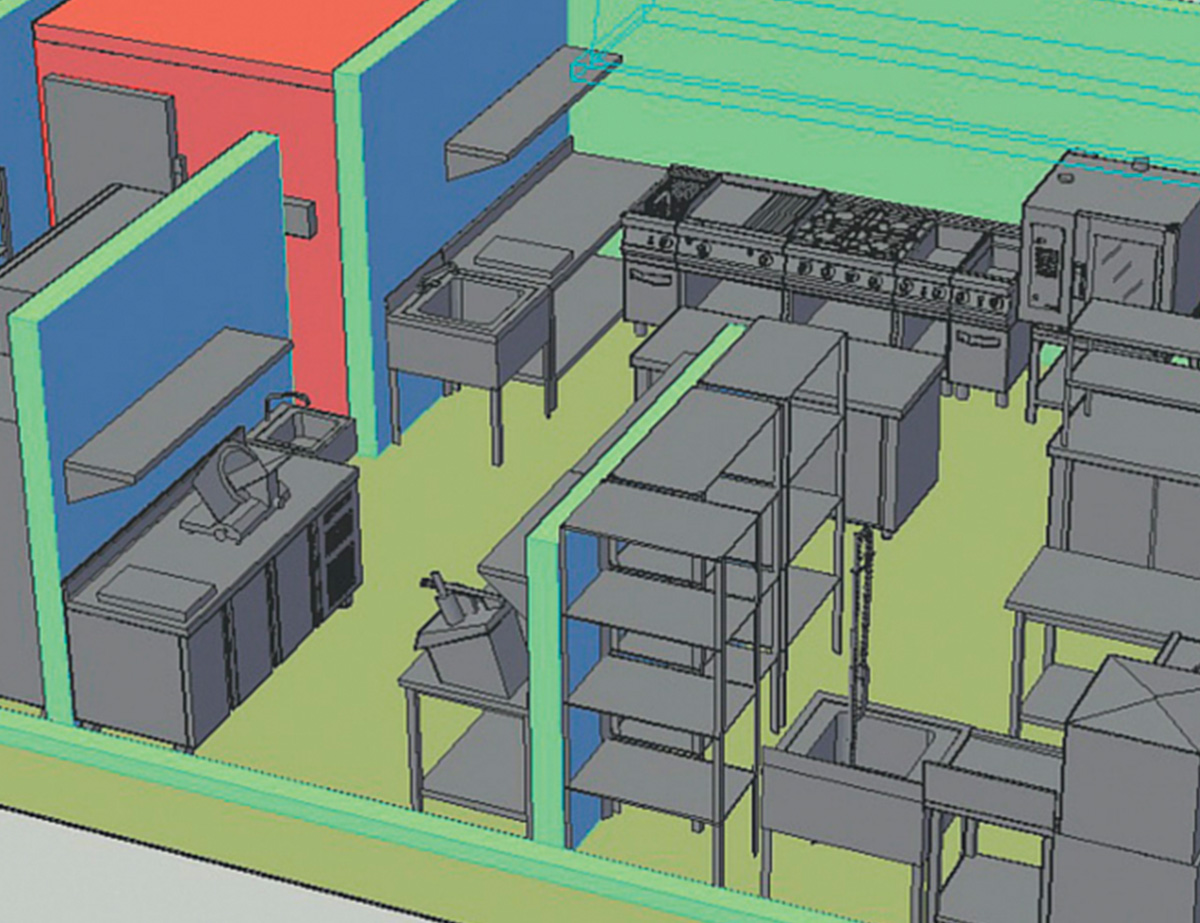

1. Analyse the possibilities and requirements of the premises: this is essential in order to achieve a good kitchen design and to get the most from the premises. The preliminary study will serve to determine the types of appliances that can be installed, how to arrange the different zones, where the access points will be, where the extraction fans and supply connections will be…

2. Make the most of the available space: after analysing the possibilities and requirements of the establishment, it is necessary to consider the available space, which will define, for example, the design type used in the premises or the size of the machinery to be installed.

3. Plan the correct layout: it is essential to consider a layout that facilitates the work flow and organisation, defining the sections or areas of the kitchen: reception, storage and refrigeration chambers, preparation, cooking, distribution and delivery, washing, pots and pan storage…

4. Equip the kitchen with the right machinery: depending on the establishment, the criteria used in one establishment or another will vary considerably. For an a la carte restaurant, which prepares a wide range of dishes every day, elements such as open burners, hotplates, combination ovens or grills are essential. On the other hand, in the case of an industrial kitchen used for large-scale production, large capacity cooking pots, fryers and frying pans, and large ovens should be considered, in addition to a washing system using a conveyor belt or rack, permitting the continuous input of large quantities of elements for washing.

5. Select the right materials for each different case: stainless steel is the number one material par excellence. Its robustness and quality guarantee the service life of the equipment in working conditions for many years, a factor of great relevance for professionals, as this type of installation always requires significant investment. Moreover, stainless steel offers optimum conditions of hygiene, health and cleanliness and a wide range of possibilities. Other types of material should also be considered for very specific uses in certain elements. These include brass (for burners), cast iron (for grills and hotplates), chrome steel (for roasting griddles)…

6. Select a design by components: this type of design makes the hygiene and maintenance processes easier, such that, in the event of a fault, the removal and replacement of one part is easier and it is not necessary to stop the work process, thereby neither affecting or delaying routine procedures.

7. Increase hygiene and cleanliness: hygiene is essential in any catering establishment, but it takes on a special significance in industrial kitchens. During cleaning tasks, as well as removing the remains of food and dirt visible to the employee, it is also essential to eliminate the non-visible dirt in the kitchen, for example, the dirt that builds up in the hoods, in the extraction pipes, in cracks and spaces…

8. Select cutting-edge technology: it is essential that, wherever possible, tasks are computerised, as this permits a large part of the daily work to be programmed and streamlined, thus making the professionals’ work easier. The use of electronic programmers in combination ovens or blast chillers, the inclusion of the HACCP system in those machines that accept it, automatic timing systems for switching appliances on /off, or even the computerisation of restaurant tasks for the service always help to improve the efficiency of the work and to obtain increased business profitability.

9. Consider energy efficiency: other factors to consider when designing a project of this nature include energy savings and energy efficiency. These days, the wide range of machines available for all areas of the kitchen offers the possibility to work more efficiently, with significant economic savings, while respecting the environment thanks to their environmentally-friendly designs. A clear example of this can be found in the new Fagor Professional E-VO dishwashers, the NEO refrigeration and the ADVANCE ovens.

“Industrial kitchens face high costs, which include both the sources of energy (mainly electricity and gas), and the water used. Consequently, increasing savings has become a priority for us and from our R&D department we have introduced improvements in efficiency in each of the new machines that we develop”, states Juan Alos, Product Manager for Fagor Professional. “It is essential to create a personalised design for the industrial kitchen so that the space is optimised to the maximum, and the professionals are able to work in greater comfort and more efficiently.”

Follow us