Freezing is a traditional method of food conservation. Through the freezing process, we are able to maintain the nutritional properties of the food, we can lengthen the shelf life of the products, reduce waste and increase the profitability of the business in the catering sector.

Today in the Fagor Professional blog, we take a look at the benefits of the blast chiller or rapid cooling system for food in an industrial kitchen. Take note!

Discovering the many advantages of blast chillers

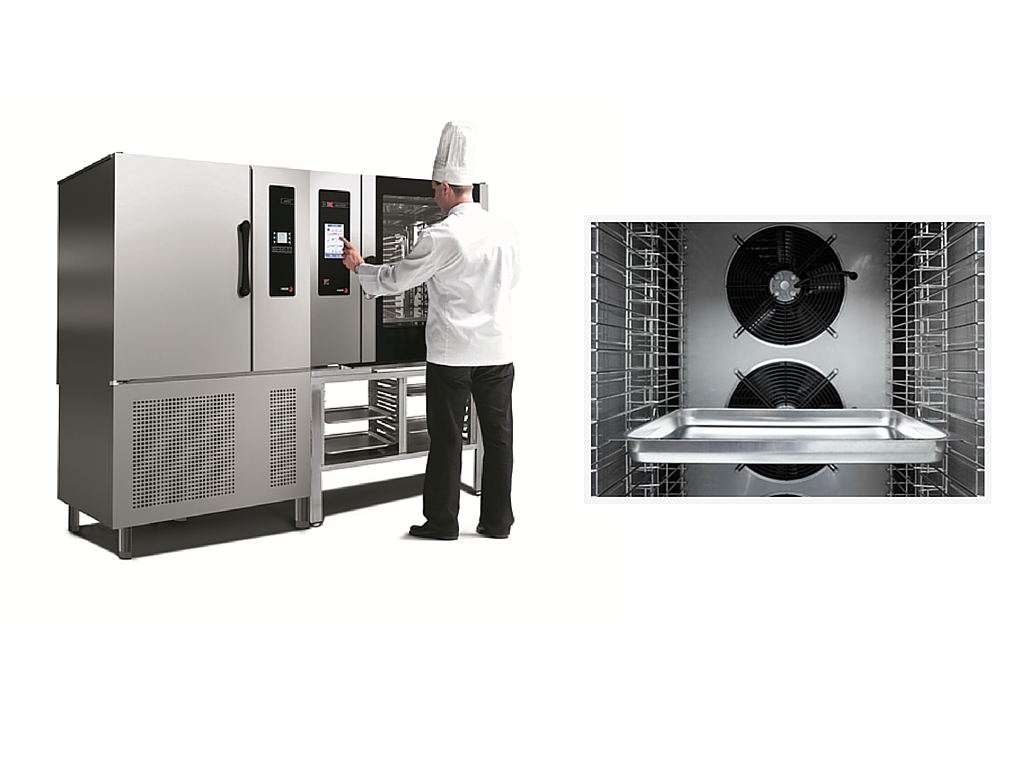

The blast chiller or rapid cooling system for food is an essential piece of equipment in an industrial kitchen. Quick freezing has a number of advantages in comparison to traditional cooling processes. One of the main characteristics of blast chillers is that they enable the internal temperature of recently cooked food to be lowered in less than two hours, thus avoiding the spread of bacteria and also maintaining the product’s optimum conditions (colour, texture, flavour, smell…).

The quick freezing process achieved with this industrial equipment results in the formation of micro-crystals inside the food, an aspect which helps to conserve the quality and ensure the safety of all types of food.

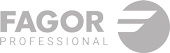

The Fagor Professional blast chillers, both for refrigeration (where the temperature of the food is lowered from +65 °C to +3 °C in less than 90 minutes) and for mixed service (refrigeration or freezing, from + 65 °C to -18 °C in less than 4 hours), range from the small tabletop appliance for 3 trays, to large blast chilling cells able to take the 20-level GN-2/1 container trolleys from our ovens.

Some of the main features of the blast chiller and blast chiller freezer (mild cycle and hard cycle) are described below:

1. Blast chiller freezing

1.1 Mild cycle (standard) – 240

This cycle freezes the product uniformly, and is therefore suitable for food that must not be subjected to sudden changes in temperature, or food which has been prepared using different ingredients.

1.2 Hard cycle (intensive) – 240

This cycle is ideal for freezing semi-finished meals or semi-prepared dishes. It is also suitable for raw food. In addition, it allows a stock of frozen products to be kept for long periods of time, for use over the year.

2. Blast chiller cooling

2.1 Mild cycle (standard) – 90

This cycle is suitable for mild, light or thin food of a limited size and volume.

2.2 Hard cycle (intensive) – 90

This is suitable for high density or thick foods, and for preparing canned or bottled food.

Lastly, it should be noted that the correct use of the blast chiller in combination with the Advance ovens by Fagor Professional (Cook & Chill System by Fagor) helps to reduce waste, save time, increase earnings and produce a flavoursome product, thus serving to boost the profitability of the business.

Follow us